Compact and lightweight (24.0Kg*1)—Easy operation characteristic of portable outboards DF6A, DF5A and DF4A. A new generation fully reborn with style.

Suzuki DF4 / DF6 Brochure. Suzuki designed the DF4 and DF6 to be compact and lightweight with added features that make their operation more user-friendly. The DF4 and DF6 are 4-strokes so you can expect clean, economical operation, and like all Suzukis, they deliver excellent power, performance and durability. Related Manuals for Suzuki DF 60. Outboard Motor Suzuki DF250SS Product Information. Sport 4-stroke outboard motor (12 pages) Outboard Motor Suzuki DF140 Setup Manual. Outboard motor (21 pages) Outboard Motor Suzuki DF 90 Service Manual (616 pages) Outboard Motor Suzuki DF9,9 Service Manual.

- S-shaft Models

More compact and much lighter

While maintaining the engine displacement of 138cm3, the conventional design has been overhauled and downsized to realize 1.0kg weight reduction (24.0kg*1). The lighter weight has improved operability.

Along with weight reduction, the carrying handle integrated into the lower cover which has been rounded and made easier to hold, and an additional grip at the front further improve its portability.

Enhanced user-friendliness

The overhead integral fuel tank and the new lubricating systems allow transport and storage of the outboard on any of three sides (port, starboard, or front) without leakage of fuel or oil.

Because the overhead fuel tank is placed right above the carburettor, it also allows gravity fuel supply, enabling the engine to start instantly right after filling fuel, even after long-term storage. These features have enhanced its user-friendliness as a portable outboard motor.

Lightweight

In addition to a reincarnated stylish appearance, the newly designed and developed Suzuki DF6A,DF5A and DF4A boast the unrivaled lightweight, 24.0Kg (S-shaft models).

The lighter weight has improved portability as well as operability.

Suzuki Df6 Owners Manual Pdf

Outstanding Handle Operation

An ease of handling that has enjoyed great popularity. Further improvements to the tiller handle have successfully mitigated vibrations contributing to fatigue and stress when transmitted to the hand during operation. The DF6A, DF5A and DF4A particularly excel at vibration mitigation in the mid-range.

Offset Crankshaft

Positioning the crankshaft slightly off center of the cylinder reduces lateral pressure against the cylinder wall as the piston moves up and down in the cylinder. The result is smoother piston movement, which improves operating efficiency.

Easy After-Storage Start

Because the integral overhead fuel tank and one-way valve allow gravity fuel supply, the engine can be started without opening the engine cover, even after longterm storage.

Quiet Operation

The low noise level is the result of a silencer, designed to optimize the capacity and shape of the air intake. The new design of the rocker arm and the plane bearing of the crankshaft also help reduce the noise level. We also changed the structure of the parts related to the rocker arm and eliminated its excessive play. In addition, we changed the crankshaft bearing from a common ball type to a plane type.

Highly Reliable Lubricating System

The forced lubrication system of the DF6A, DF5A and DF4A has an additional oil passage to the upper and lower crankshaft and connecting rod big end. The addition of a first-in-its-class** oil filter greatly increases the reliability of the lubricating system. Furthermore, the new position of the oil window allows for visual confirmation of the actual lubricating condition.

Three-Way Storage

The new fuel and lubricating systems allow extremely convenient storage of the outboard on any of three sides (port, starboard or front) without worrying about the storage orientation.

Improved Portability

The carrying handle integrated into the lower cover has been rounded and made easier to hold. An additional grip at the front of the lower engine cover provides the convenience of carrying the outboard with both hands.

New Tilt System

The tilt system of the DF6A, DF5A and DF4A offers different up-and-down paths of the shallow drive arm compared with the previous models. When raised, it can be locked at three positions. When lowered, it can just be smoothly moved to its lowest position without locking.

Suzuki's Anti Corrosion System

Suzuki protects its outboards with an anti-corrosion finish specially developed by Suzuki. Applied directly to the aluminum surface it maximizes the bond between the finish and the surface, increasing the protection and durability of parts that are constantly exposed to saltwater.

Lower Emissions, Efficient Operation

Suzuki's advanced four-stroke technologies deliver highly efficient operation and lower emissions. This allows Suzuki outboards to conform to some of the world's strictest standards*3 including the EURO 1 Emissions Standards (Directive 94/25/EC as amended by Directive 2003/44/EC)*4, and receive a three-star rating from the California Air Resources Board (CARB).

*3:Emission standards compliancy is region specific.

*4:The EU emissions standards (exhaust gasesand noise levels) set by the European Parliament and Council.

| MODEL | DF6A |

|---|---|

| RECOMMENDED TRANSOM HEIGHT mm | S:381, L:508 |

| STARTING SYSTEM | Manual |

| WEIGHT kg *5 | S:24, L:25 |

| ENGINE TYPE | OHV |

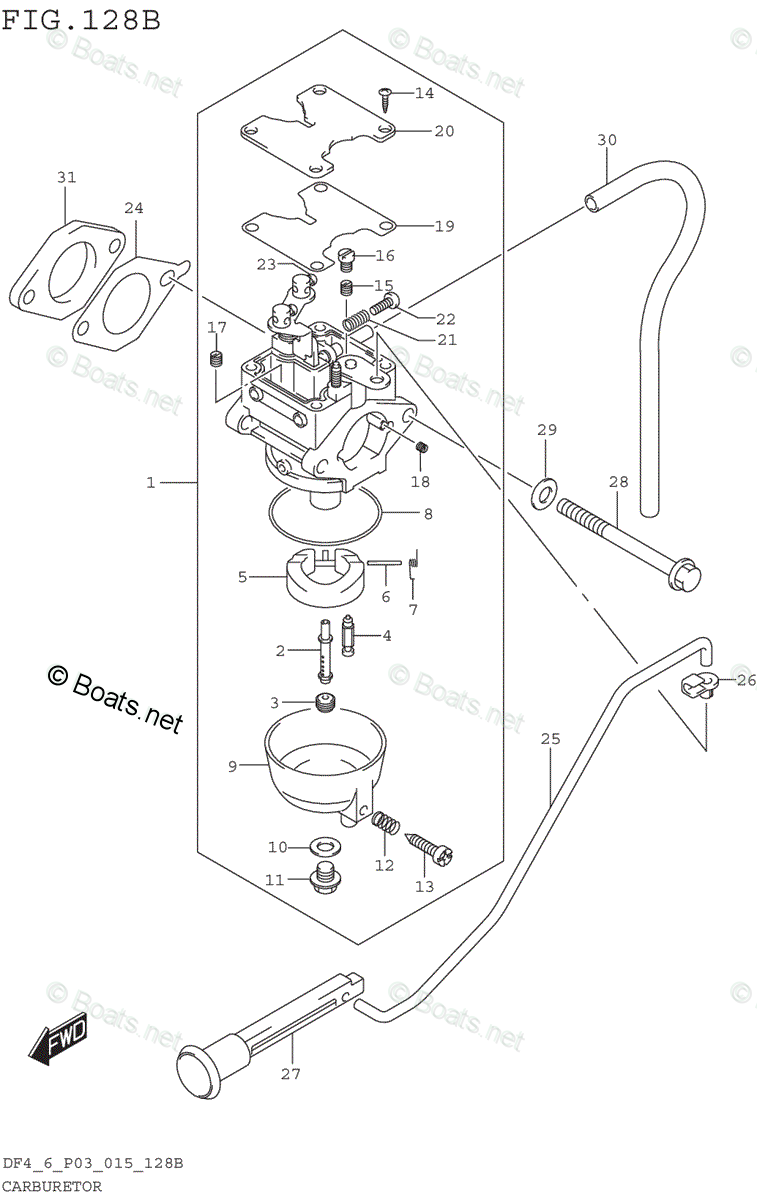

| FUEL DELIVERY SYSTEM | Carburetor |

| NO. OF CYLINDERS | 1 |

| PISTON DISPLACEMENT cm3 | 138 |

| BORE ×STROKE mm | 60.4 X 48 |

| MAXIMUM OUTPUT kW | 4.4 |

| FULL THROTTLE OPERATING RANGE rpm | 4,750-5.750 |

| STEERING | Tiller |

| CHOKE | Manual |

| OIL PAN CAPACITY Lit. | 0.7 |

| FUEL TANK CAPACITY Lit. | Integral 1.0 |

| IGNITION SYSTEM | Digital CDI |

| ALTERNATOR | 12V 5A (Option) |

| ENGINE MOUNTING | Bushing Type |

| TRIM METHOD | Manual Trim and Tilt |

| GEAR RATIO | 1.92:1 |

| GEAR SHIFT | F-N-R |

| EXHAUST | Above Prop Exhaust |

| PROPELLER SELECTION (Pitch) *6 All propellers are the 3-blade type | 6'-7' |

| MODEL | DF5A |

|---|---|

| RECOMMENDED TRANSOM HEIGHT mm | S:381, L:508 |

| STARTING SYSTEM | Manual |

| WEIGHT kg *5 | S:24, L:25 |

| ENGINE TYPE | OHV |

| FUEL DELIVERY SYSTEM | Carburetor |

| NO. OF CYLINDERS | 1 |

| PISTON DISPLACEMENT cm3 | 138 |

| BORE ×STROKE mm | 60.4 X 48 |

| MAXIMUM OUTPUT kW | 3.7 |

| FULL THROTTLE OPERATING RANGE rpm | 4.500-5,500 |

| STEERING | Tiller |

| CHOKE | Manual |

| OIL PAN CAPACITY Lit. | 0.7 |

| FUEL TANK CAPACITY Lit. | Integral 1.0 |

| IGNITION SYSTEM | Digital CDI |

| ALTERNATOR | 12V 5A (Option) |

| ENGINE MOUNTING | Bushing Type |

| TRIM METHOD | Manual Trim and Tilt |

| GEAR RATIO | 1.92:1 |

| GEAR SHIFT | F-N-R |

| EXHAUST | Above Prop Exhaust |

| PROPELLER SELECTION (Pitch) *6 All propellers are the 3-blade type | 6'-7' |

| MODEL | DF4A |

|---|---|

| RECOMMENDED TRANSOM HEIGHT mm | S:381, L:508 |

| STARTING SYSTEM | Manual |

| WEIGHT kg *5 | S:24, L:25 |

| ENGINE TYPE | OHV |

| FUEL DELIVERY SYSTEM | Carburetor |

| NO. OF CYLINDERS | 1 |

| PISTON DISPLACEMENT cm3 | 138 |

| BORE ×STROKE mm | 60.4 X 48 |

| MAXIMUM OUTPUT kW | 2.9 |

| FULL THROTTLE OPERATING RANGE rpm | 4.000-5.000 |

| STEERING | Tiller |

| CHOKE | Manual |

| OIL PAN CAPACITY Lit. | 0.7 |

| FUEL TANK CAPACITY Lit. | Integral 1.0 |

| IGNITION SYSTEM | Digital CDI |

| ALTERNATOR | 12V 5A (Option) |

| ENGINE MOUNTING | Bushing Type |

| TRIM METHOD | Manual Trim and Tilt |

| GEAR RATIO | 1.92:1 |

| GEAR SHIFT | F-N-R |

| EXHAUST | Above Prop Exhaust |

| PROPELLER SELECTION (Pitch) *6 All propellers are the 3-blade type | 6'-7' |

*5:Dry weight: not including propeller and engine oil

*6:Please inquire at your local dealer for details of the propeller

The appearance, colors, and equipment of outboard motors may differ according to market and grade.

Specifications may change without prior notice.

*Manufacture data

PROMOTIONAL VIDEO

Get information for your country or region.

RELATED SUZUKI OUTBOARD SEARCHES:

PROPELLERS

An outboard motor is designed to develop its rated power within a specified engine speed range. The maximum rated power delivered by the Suzuki models are shown in your service manual. If the standard propeller fails to meet the above requirement, use another pitch propeller to hold the engine speed within the range specified in your manual propeller selection chart.

Installing a propeller with pitch either too high or too low will cause incorrect maximum engine speed, which may result in severe damage to the motor.

Disassembly of propeller shaft components

1. Slide propeller shaft away from reverse gear housing assembly

Account for reverse gear back-up shim thrust washer

2. Remove horizontal slider and forward gear thrust washer

3. Remove spring

4. Using special tool, push dog pin shifter.

5. Remove clutch dog shifter propeller shaft.

PROPELLER

• Inspect propeller for bent, chipped or broken blades and replace or repair if necessary.

• Inspect propeller bushing splines for wear or other damage and replace if necessary.

• Inspect propeller bushing for deterioration or slipping and replace if necessary.

PROPELLER SHAFT COMPONENTS

• Inspect horizontal slider and connector pin for excessive wear or other damage. Replace if necessary.

• Inspect clutch dog shifter for excessive wear, chip or other damage. Replace if necessary.

• Inspect dog pin for bent or other damage. Replace if necessary.

• Inspect propeller shaft / splines for wear, twist or other damage. Replace if necessary.

PROPELLER SHAFT BEARING HOUSING

• Inspect housing for cracks or other damage. Replace if necessary.

• Inspect propeller shaft bearings and reverse gear bearing for pitting, rough or other damage. Replace if necessary.

• Inspect oil seals and O-ring for cuts, nicks or tears.

Replacing propeller shaft oil seal

1. Remove retaining ring

2. Extract oil seals

1 and washer 2.3 using oil seal remover.

Do not re-use oil seal once removed.

Always use a new oil seal.

3. Apply Water Resistant Grease to inner circumference of housing.

4. Using an oil seal installer, drive two oil seals (one at a time) into housing.

The lipped portion of seal should face towards propeller.

Apply Water Resistant Grease to seal lips.

5. Install washer and retaining ring.

PROPELLER INSTALLATION

Suzuki Df6 Outboard Owners Manual

1. Install spacer shaft, then slide on propeller

2. Fit spacer specified torque.

1 and propeller stopper 2 onto propeller3.4, washer 5 and nut 6, then tighten nut to

Propeller nut : 55 N.m (5.5 kg-m, 40.0 lb.-ft.)

3. Push cotter pin secure.

PROPELLER SELECTION FOR COUNTER

ROTATION

For counter-rotation model, newly designed stainless steel propellers are available as follows.

Suzuki highly recommend to use the genuine Suzuki counterrotation propeller for the counter rotation model. In case of twin installation, always use on both engines, the same size normal rotation and counter-rotation propellers.

ENGINE CRANKED, BUT NOT START (OR STOPS SHORTLY AFTER STARTING)

UNSTABLE IDLING / TROLLING (OR ENGINE TENDS TO STALL)

Suzuki Df6 Owners Manual

• Incorrect by-pass air screw adjustment [NOTE3]

• IAC valve failure [NOTE3]

• IAC passage failure (clogged hose, etc.) [NOTE3]

• Spark plug failure

• Ignition coil failure

• ECM failure

• Wire continuity / connection failure

• Failure of high pressure fuel system components :

• Fuel injector (clog, stuck valve, etc.)

• Fuel pressure regulator (incorrect regulated pressure, etc.)

• Fuel pump (clogged suction filter, leakage in tank, etc.)

• Fuel filter (clog, etc.)

• Hose (clog, kink, leakage, etc.)